Choosing the right trimming machine for your cannabis depends on various cultivar characteristics, like flower quality, size, and density. To help alleviate some of the pressure of selecting an appropriate trimming machine, Keirton has teamed up with Growing Exposed, celebrating Growing Exposed’s YouTube channel reaching 100,000 subscribers with a giveaway contest. Twister Trimmer is the primary sponsor of this giveaway, which was announced on April 1, 2021, and will run until May 15, 2021. Along with $15,000 worth of giveaway prizes, contest entrants have a chance of winning the grand prize, a Twister T4 Trimmer.

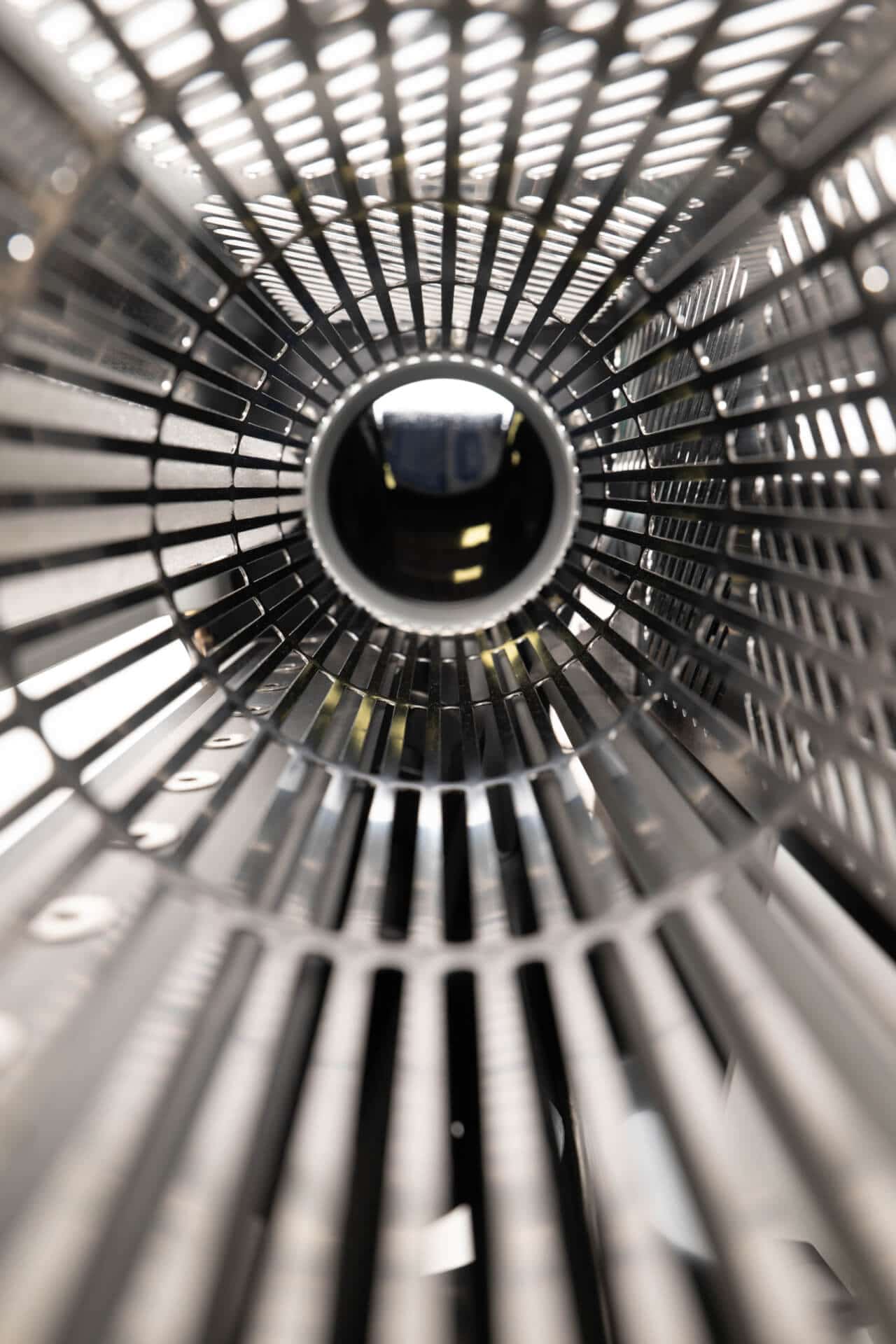

The Twister T4 Trimmer is one of the most popular trimmers across the industry, with more than 6,200 in use globally. Built to meet the demands of medium- to large-scale cannabis and hemp producers, the T4 Trimmer shines in versatility, mobility, trim quality, and ease of use. However, while machine-trimming can certainly optimize the cultivation process, following best practices is imperative to a successful, bountiful harvest.

Machine-Trimming Best Practices

One of the most important post-harvest considerations is whether to opt for wet trimming or dry trimming. This is a decision you need to make before setting up the drying rooms, as it will determine the order in which you trim and dry the cannabis. Dry trimming requires the flower to go through the drying process prior to trimming. While this method comes with a higher risk as the machine’s capabilities are dependent on whether the flower is properly dried, the end product will typically have a more favourable aroma. Wet trimming is the easier of the two machine-trimming methods because it does not require a pre-drying process. However, a notable downside is that wet trim will cauterize when cut, leaving a cut-grass smell.

Cannabis is quite sensitive to temperature, humidity, and airflow. It is important to trim in a cold, dry room. It’s also imperative to avoid touching the flower as much as possible, especially before it has been completely dried. Trichomes are quite sticky when wet, and increased contact and handling will result in a loss of trichomes. This is why properly drying the cannabis is so important before dry trimming; while drying too quickly can result in terpene loss and the degradation of THC, drying too slowly can result in mold developing. Managing the drying process helps to prevent damaging the flower, and allows you to better manage THC, terpene, and cannabinoid levels. This can increase your control over the profile, terpenes, flavour, aroma, and quality of your final product. In fact, commercial cultivators are beginning to move away from wet trimming, opting for the added control and quality that dry trimming allows.

Finally, it’s important to keep large buds intact, avoiding cutting stems, which give the plants structure and stability. Remember, if the product can crumble in your hand, it will crumble in the machine. Monitoring and maintaining a sufficient moisture profile will cause the outside leaves to be crispy while the center of the bud is moist. A proper drying technique and vacuum adjustment will ensure large buds stay large.

Advantages of Machine-Trimming

Hand-trimming has traditionally been the method of choice for cannabis cultivators who have a deep appreciation for production as a craft and preserving the art of cultivation. However, commercial demands require cultivation methods that are not impeded by time- and labour-intensive practices. Over the years, innovation in cultivation engineering has seen the exponential growth of trimming-machine capabilities, enabling them to keep up with medium- and large-scale harvests, while preserving cannabis quality and potency. Keirton currently equips approximately 80 percent of the industry’s leading legal cannabis producers across more than 30 countries with custom cannabis technology.

Speed

Machine-trimming offers a few key advantages that hand-trimming simply cannot compete with, and can work for both wet or dry trimming. The Twister T4 Trimmer is capable of trimming up to 23 pounds per hour for wet trimming for a single unit. It can also run in configurations up to three in a row, for a total production speed of up to 78 pounds per hour. For dry trimming, this trimming system is capable of reaching a rate of 7 pounds per hour for a single unit, or 16 pounds per hour for two configurations in a row.

Cost Efficiency

Reducing the labour required for harvest is the simplest form of cost-savings. Machine-trimming is significantly less time- and labour-intensive than hand-trimming, requiring a smaller workforce despite increased harvest volume. However, labour reduction extends beyond the harvest to include the logistics of a large workforce; requiring fewer employees, machine-trimming reduces the workload for human resources and payroll. Another key point to remember is that machines don’t create moisture; rather, this is caused by more hand trimmers in the room. Less populated facilities require less air conditioning and dehumidification. Additionally, machine trimmers reduce product waste, allowing cultivators to increase profits. Trim can be saved after going through a machine trimmer, and can be used for byproducts.

Quality

How you manage and maintain your plants throughout the growing process will be the primary indicator of cannabis quality. While you can never increase the quality once you have harvested, you can certainly ruin it. The speed at which machine-trimming can process a harvest prevents post-harvest bottlenecks, which can otherwise lead to bud rot if dry room and growing facility conditions, including humidity and poor ventilation, facilitate mold and mildew development. By taking the time to find the correct settings, you can ensure the machines will be gentle; with a controlled environment, maximum trichomes can be kept on the flowers.

Safety

The right trimmer can enhance the safety of its operators. The Twister T4 Trimmer’s minimal, stainless-steel design is easy to clean and able to withstand direct, high-pressure washing and harsh chemicals. The T4’s CE, CSA, and UL certifications are a testament to the machine’s safety. However, an often overlooked element is the safety of the conveyors. The T4 Trimmer allows operators to work three feet away from the tumbler and blades, rather than requiring them to put their hands in the hopper to load it. This eliminates any risk of injury, and dramatically improves the overall safety of the machine.

Revenue

Proponents of machine-trimming know that dramatically increasing the processing volume, preventing bottlenecks to reduce damaged buds and product loss, and reducing the labour costs all lead to a massive revenue growth. However, even many anti-machine trimmers are slowly moving towards machines for a light first pass. This allows the machines to run at a higher throughput than normal while still doing 80% of the work. With this method, hand trimmers can still preserve their craft, following the machine to manually give the hand-trimmed look to improve the appearance and gain the highest revenue per pound.

Choosing the Right Bud Trimmer

With so many options available, how is a grower to know which is the best machine trimmer for their particular operation? An operator’s choice should be based on the volume that needs to be harvested, and the speed at which it needs to be harvested. The Twister T4 Trimmer is ideal for adapting to the variability in cultivar characteristics for medium- to large-scale harvests. However, for larger commercial cultivation, the Twister T-ZERO Pro does the work of more than 15 T4 Trimmers, processing up to 600 pounds of wet or 125 pounds of dry cannabis, and is built to run for 24 hours straight, maximizing throughput.

Regardless of the size of the harvest, technology is proven to enhance efficiency, reduce product loss, and increase throughput and revenue. Whether you opt to use only machine-trimming, or prefer the craftsmanship that manual hand-trimming can offer after light machine processing, technology companies like Keirton are constantly innovating in order to improve profitability and meet the evolving needs of cannabis cultivators.