How is Cannabis sorted?

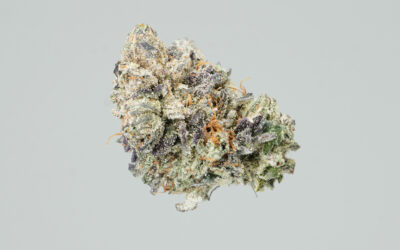

Sorting Cannabis has long been a practice performed by cultivators. In the early days, it was simply to remove the shake that was produced after drying. Bag appeal helps differentiate from competitors, so ensuring there was no shake was a widespread practice. As the cannabis market evolved, the market began to differentiate higher levels of quality by flower size. Bigger buds are often worth more than smaller buds, both in the Recreational and Legacy markets. To an outsider of cannabis, this would seem odd, “If I’m buying flower by weight, why do I want to buy a big nug with so much stem inside that I will throw away?” Large flowers typically indicate top colas and are well known as the premium part of the plant. They test higher in cannabinoids, are more colorful and denser in comparison to smaller lower flowers.

In the past sorting cannabis was typically done with different-sized wire or fabric screens. Many would build DIY sorting solutions. More recently, automation has become increasingly popular. With wholesale cannabis prices so low, the cost of production is becoming critical. Manually sorting over stationary screens can be labor intensive.

What sizes is cannabis sorter for?

Flower is now often sorted into 3 primary sizes in most regions.

- Shake / micros: typically, 1/4” and smaller.

- Smalls or B buds: 1/2” and smaller.

- Bigs or A buds: 5/8” or 3/4” and bigger.

What is the best cannabis sorter?

There are a few types of automated cannabis sorters. Most will do over 100 lb. an hour, so speed is not typically a big issue. The best cannabis sorters are:

- Circular Vibratory Sorters are made by companies such as Kasson. These can work well for sorting and are very accurate; however, they are the most complicated of the various sorters, they often require maintenance and they require an operator to be present to constantly monitor and load the machine. If the sorter requires an operator, ensure you add that to the cost of the sorter. Also, most have coated or painted surfaces that do not meet strict sanitary requirements and coatings often peel or flake. Some argue the vibration from these sorters reduce potency by shaking off trichomes, however, reports from many cannabis producers testing data cannot prove this claim.

Band Sorters are made by companies such as Mobius M9 or Greenbroz. These machines use large rubber bands connected to rollers to separate out different sizes. This style of sorter is faster than a circular vibratory sorter, however, the rubber bands tend to break, the accuracy is low as they only offer one dimension, and they are exceedingly difficult to clean – particularly the bands. Using isopropyl alcohol or other cleaners dry the bands out, and this makes them crack and break – causing downtime. These systems also require an operator to be present to feed the machine. Some will try to overcome this with a rise conveyor. Unfortunately, an operator is still required to feed the machine – ensure you add these to the cost of the solution. Rise conveyors often damage flower due to the cleats or paddles, so keep this in mind when analyzing this option.

Band Sorters are made by companies such as Mobius M9 or Greenbroz. These machines use large rubber bands connected to rollers to separate out different sizes. This style of sorter is faster than a circular vibratory sorter, however, the rubber bands tend to break, the accuracy is low as they only offer one dimension, and they are exceedingly difficult to clean – particularly the bands. Using isopropyl alcohol or other cleaners dry the bands out, and this makes them crack and break – causing downtime. These systems also require an operator to be present to feed the machine. Some will try to overcome this with a rise conveyor. Unfortunately, an operator is still required to feed the machine – ensure you add these to the cost of the solution. Rise conveyors often damage flower due to the cleats or paddles, so keep this in mind when analyzing this option.- Flow Through Sorters such as the S1 Sorter are newer to the market. These sorters are highly accurate like a vibratory sorter, fast like a band sorter and they auto-feed the cannabis – allowing you to spend time doing something else. As the cannabis world moves to stricter regulations such as food processing and pharmaceutical, ensuring the sorter can be thoroughly washed down is critical. Look for all stainless-steel components, not simply the product path. This ensures a long-lasting machine that can handle the most intense cleaning process.

- If you are looking for sorting and grading together, you may want to consider the more advanced options such as Marvel AI. Marvel is an AI powered vision system that inspects both sides of every flower – then grades and sorts based on your criteria. Grading is becoming increasingly important when bulk flower purchases take place – in many industries, this is called custody transfer. Knowing the grade of every flower in a 100lb batch and an overall score of the entire batch is now possible. Brands are built on consistency, and Marvel allows greater assurance of that consistency. Quality assurance teams at cannabis producers now have a new tool to look for mold and foreign material.

Do cannabis sorters hurt potency?

There is no detectable decrease in potency from automated cannabis sorters. While there may be some trichome loss, it is not in sufficient quantities to be detectable in lab testing.

Why use a cannabis sorter?

Once sorted by size, the value of each size will vary. Example: Shake may sell for $50 a pound. Small flowers (smalls or B-buds) may sell for $200 – $300 a pound. Large flower of the same lot may sell for $800 – $1000. Sorting cannabis into sizes typically provides a higher average selling price for the entire lot.

Some packaging machines require specific flower sizes, and sorting cannabis prior to these machines is required.

Sorting Cannabis is very time consuming. One skilled person can properly sort cannabis at a rate of 5 – 10 pounds per hour. Automated sorters are 30x faster.

If the sorter has an auto feeder – meaning an operator is not required to feed the sorter – ROI is extremely fast.

Do I need a cannabis size sorter?

At some point in the process, Cannabis flower is always sorted. This may simply mean removing the shake from the flower. Some cannabis companies need 3-4 sizes for distinct products and brands. Shake can go to extraction. Micros can go to pre-rolls. Smalls can go to the value brand. Large flowers are reserved for the top shelf brand.

Conclusion

If you plan to be competitive in the cannabis space, at some point cannabis sorting is necessary.

See the Latest Cannabis News

Automated Grading in Cannabis: Revolutionizing Quality Control with Advanced Vision Systems

Introducing a state-of-the-art automated cannabis grading machine, revolutionizing quality control.

Unveiling the Future: Marvel Gen 2

We are thrilled to announce the arrival of Marvel Gen 2, the latest...

A Marvel-ous Evolution in Cannabis Consistency

In today's fast-paced market, consumers demand consistency. They...

The Ultimate Nerds Guide to Curing Cannabis

We’ve created multiple guides to curing cannabis to share with you.

The Dawn of a New Quality Era in (Grading) Cannabis

As the cannabis industry blossomed, consumers became ever more...

Elevate Your Cannabis Production Quality: Unlocking the Power of Continuous Employee Training

In today’s cut-throat cannabis market, merely achieving exceptional...

Save Millions of Dollars

A million-dollar question deserves a million-dollar answer:A...

The Complete Guide to GMP Certification in the Cannabis Industry

GMP is a popular topic among the cannabis industry and its...

Cannabis Automation

Why Cannabis Automation is Important Cannabis automation has become...

The Hidden Costs of Commercial Cannabis Trimming Machines

Uncovering the Hidden Costs of Commercial Cannabis Trimming...

How does cannabis dust affect air quality?

As the cannabis industry evolves, many regions are now tightening up...

Trimming Machine Throughput Called Out

As the cannabis industry continues to develop, there is a lack of...

Cannabis Flower Brands with Consistency Win

Cannabis flower brands that are consistent have a much better chance...

How Loud is a Cannabis Trimming Machine?

Are Cannabis Trimming Machines Loud? The noise from cannabis...

How Important is Uptime in Cannabis Processing Facilities?

Understanding the Importance of Uptime in Cannabis Facilities Uptime...

How to Choose a Cannabis Trimming Machine

As the cannabis industry continues to grow, so does the need for...

Protecting Cannabis Brand Reputation

Grammy Award nominated Don Carlos – Protecting a brand As the owner...

Take the Trim Challenge – Hand Trim vs Twister

Think you have what it takes? One of the images below is trimmed by...

Trimming Craft Cannabis with Twister T4

*Transcribed from video above The Twister Grow Facility -We don’t...

Twister T4 Trimmer Spotlight and Giveaway

Choosing the right trimming machine for your cannabis depends on...

What to Consider when Drying and Curing Cannabis

Drying can be one of the most challenging parts of the cannabis...

Behind The Harvest – Ep 01 w/ Justin Cooper of Growing Exposed

In the inaugural episode of Behind The Harvest, Paul is joined by a...

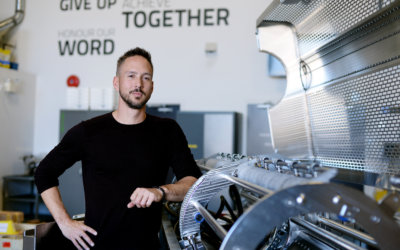

Keirton Named One of Canada’s Top Small and Medium Employers for 2021

It’s with immense pride that we announce that Keirton has been named...

Cannabis Growth Considerations: How to Prevent Post-Harvest Rot

After a lengthy growing season, you’re finally harvesting your crop...

How to Trim Cannabis Plants: Ensuring Cannabinoid Potency and Quality

The quest for high quality cannabinoids doesn’t end when the plant...

Global CBD Statistics 2021

Global CBD Statistics 2021 CBD oil is most popular in the United...

Marijuana Statistics USA 2021

As you’re probably already aware, different states have very...

Product Spotlight: Twister T2

| Choosing the right machine for your cannabis trimming depends...

Cooked With Cannabis’ Review

Photo Courtesy of Netflix Television viewers have always had a bevy...

Marijuana Legalization in Canada and the USA

Cannabis is fully legalized in Canada and in some states in the USA....

Forbes Feature : CEO Jay Evans

Keirton CEO Jay Evans is taking his passion for innovation, trimming...

Differences Between Marijuana and Hemp

Cannabis, marijuana, and hemp are commonly used interchangeably...

Difference between THC and THCA

Tetrahydrocannabinol (THC) and tetrahydrocannabinolic acid (THCA)...

Cannabis Market Trends During COVID-19

The outbreak of the 2020 Coronavirus has undoubtedly taken a toll on...

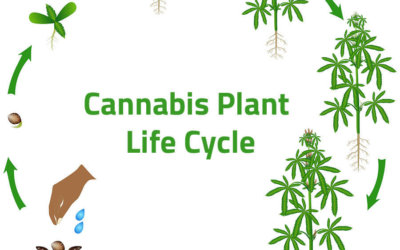

From Seed to Bud: The Plant Life Cycle of Cannabis

The popularity of marijuana plants is rife at different...

Cannabis as a Superfood

Cannabis is rich in natural nutrients that can boost the immune...

Starting your First Grow: When to Trim Your Cannabis

Over the years, cannabis trimming has been a controversial topic...

What to do with Cannabis Trim

Cannabis trim is a term referring to all waste obtained after...

The Best 5 Trimmers for All Your Needs

Trimming marijuana after harvesting is a delicate process that...

How to Maximize Cannabis Yields

Yield is not all about the amount of cannabis harvested,...

Wet Vs Dry Trimming

Bud trimming refers to removing all unwanted plant materials around...

How to Dry Trim

Dry trimming cannabis is a crucial step in determining the quality...

Product Spotlight : Batchone Dry Trimmer

Product Spotlight : Batchone Dry Trimmer Growing cannabis takes a...

How to Get the Most Profit from your Hemp Harvest

If you haven’t already, it’s time to start thinking about harvesting...

The Power of Automation for Harvesting Cannabis: Cultivate Podcast Ep. 10

In May 2018, while attending Lift Expo in Toronto, we sat down to...

Cannabis Trimming Tips: How Dry is Dry?

LEARNING WHEN TO DRY TRIM IS A HIGHLY UNDERRATED SKILL. Like really,...

Optimizing Your First Use – Dry Trimming with the Twister T4

Getting ready to trim your first crop of dry harvest? Watch this video to optimize your Twister T4.

It’s Here!! The Twister B4 Bucker

Bucking cannabis on a large scale sucks. But it doesn’t have to. The...

When to Harvest Your Cannabis: Check Your Trichomes

It’s not easy to be patient with your garden when it’s filled with...

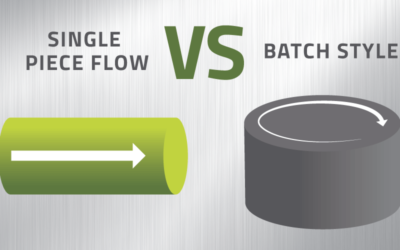

Cannabis Trimming Machine Comparison: Batch Style Trimming Machine vs. Single Piece Flow

The two most common styles of cannabis trimming machines differ...