How to Dry Trim

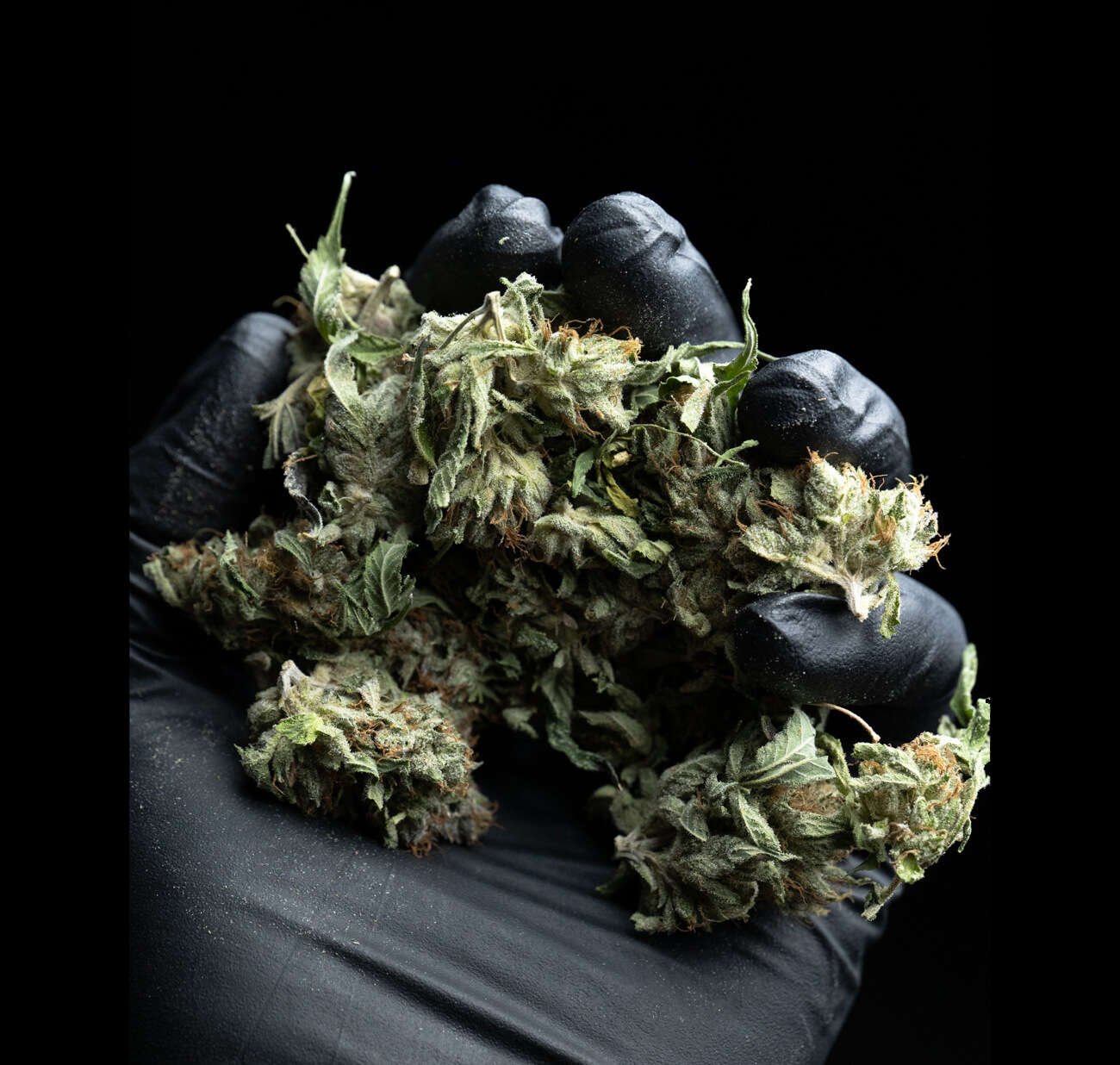

Dry trimming cannabis is a crucial step in determining the quality of smoke. The introduction of trimming machines is making the trimming process easy. Before starting, the flower buds must be allowed to dry before they are taken to the machine for trimming. The person drying the flowers must measure the moisture content.

On average, the moisture content should be maintained at 11%. A high moisture level would result in chlorophyll getting inside the flower and affecting the smoothness of the smoke. On the other hand, allowing the moisture levels to go below 8% leaves the flower vulnerable. A slight touch would cause it to crumble, hence affecting the shape and quality of the bud.

Immediately after the marijuana plant is harvested, it is hanged to drain excess water. The plant should be hanged in a dry place with a shelter to allow the water to drain naturally while maintaining THC levels. The moisture and sugar levels go down significantly. The low levels cannot drip into the buds of the marijuana since it would affect the natural smell and taste of marijuana.

Things to Consider When Preparing Marijuana for Trimming

Trimming is a delicate process, and failure to observe the process might affect the best quality of the final product. When trimming buds, you should consider:

Frequency of Loading Marijuana into the Cannabis Trimmer

Loading buds into the cannabis trimmer machine should be carried out at a constant rate for optimal and best results. Loading the buds at a fast pace might slow down the operation of the machine, which might also result in breakdown or semi-trimmed buds. On the other hand, if the buds are placed at a low frequency, they might be over trimmed, which damages their shape and causes them to crumble easily.

The standard rate of feeding the machine with buds is between 10 to 15 seconds. This range allows the trimming machine to remove any unwanted materials effectively.

The Angle at which the Marijuana Trimmer is Placed

The angle at which the machine is placed affects the appearance and quality of the buds. If it’s is placed at a steep angle, the buds might move too slow or fast for processing. Setting the machine at a steep descending angle might cause the machine to clog, or allow some buds to pass without full trimming.

On the other hand, an upward slope might cause the machine to strain, slowing down the trimming process. The standard angle for processing the flower buds should, therefore, be 0.5 inches. Th angle allows buds to move freely into the trimming chamber and is applied in industries that carry it for sale.

Size of the Marijuana Buds

The size of the hemp buds affects the quality of the final product. It is advisable to use a relatively medium size. This allows the buds to get enough time in the machine for best and proper trimming.

The Process of Trimming Marijuana

Loading Marijuana Buds into the Chamber

When loading the buds into the machine, it is best to start small. Loading small volumes at first allows the machine to adjust itself. After it’s adjusted its work, the load can be increased gradually. However, caution should be taken to avoid loading more than the machine can trim. Overloading often results in semi-trimmed buds, resulting in the poor taste of smoke.

Allowance in the Trimming Chamber

When the buds have entered into the trimming chamber, they should be given an allowance of 10 to 15 seconds. This allows the trimming to be carried out to completion. However, buds with lower moisture levels should take a shorter time in the trimming chamber to lower the risk of crumbling.

Examination of the Final Product

After trimming, the final product should be examined for its quality. The examination should be carried out after the first sample has come out. Depending on the quality of the trimmed buds, adjustments on the speed of the machine, the amount of product loaded into the tumbler, and the angle of the machine can apply. This process is effective for sale and domestic consumption.